eis corrosion testing

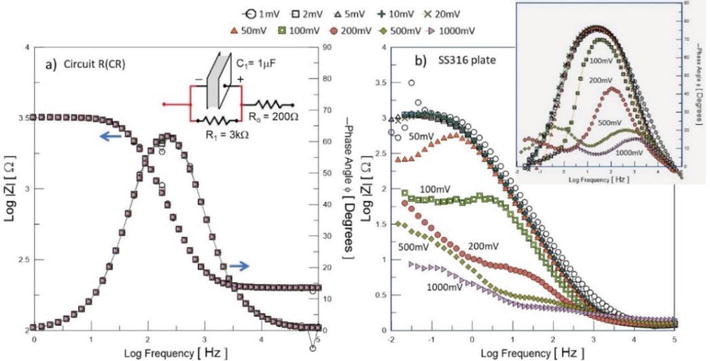

The time that samples can resist against corrosion is the criterion used to understand test sample durability. EIS measures impedance of the coating at different frequencies.

Electrochemical Impedance Spectroscopy Eis A Review Study Of Basic Aspects Of The Corrosion Mechanism Applied To Steels Intechopen

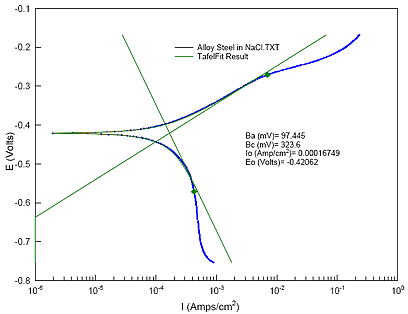

The corrosion current Icorr can be calculated when the overpotential approaches zero and is related to RP as followsIcorr1Rpbabc2303 babcIcorr1Rpbabc2303babc E6 where ba and bc are the so-called anodic and cathodic Tafel slopes or Tafel parameters respectively cf.

. Quantitative analysis of corrosion kinetics using FT-EIS EIS can be used for quantitative investigation of surface chemistries that are associated with corrosion reactions and FT-EIS can further expand the analytical framework of this approach by adding its time-resolved capabilities. EIS technique is used to evaluate materials and coatings in corrosive environments. Corrosion testing in additive manufacturing.

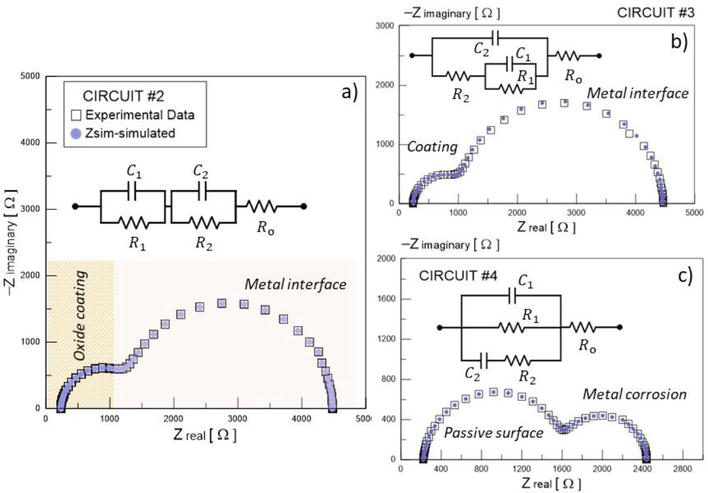

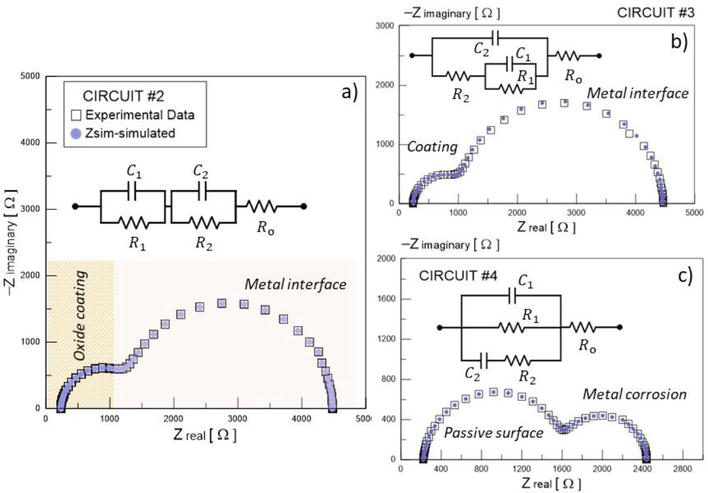

This is an indication of barrier effect of the coating. Barrier coating will exhibit high impedance in corrosive exposures. Typical investigation made with EIS are for instance deterioration of protective paints on metals or coatings in batteries but also precipitation of corrosion products.

The conclusion was that EIS did have a part to play in conjunction with accelerated weathering Autoclave and Atlas Cell tests to assist in the determination of expected coating life. Dustin explored the benefits of using EIS after atmospheric testing to assess a coatings life expectancy. Corrosion Using Electrochemical Impedance Spectroscopy EIS Method for a Better Understanding of the Corrosion System By.

This technique has now been adopted by Aramco and. EIS measurements can be combined with an accelerated degradation test in the lab to better understand the degradation of the coating and to reduce test times. However many conventional corrosion monitoring setups are bulky and.

Lujie Ye The corrosion rate is controlled by different factors such as pH temperature electrochemical potential electrolyte and as well as the applied corrosion control method. Wingepark 43 3110 Rotselaar 32 16 39 60 00. Here a 5 NaCl solution is atomized in a chamber at a temperature adjusted to 95F 35C.

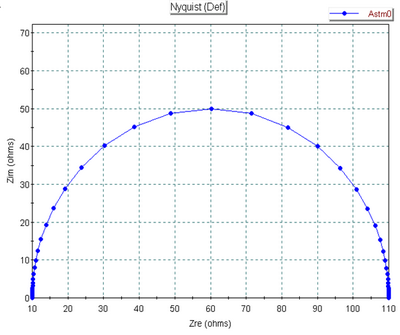

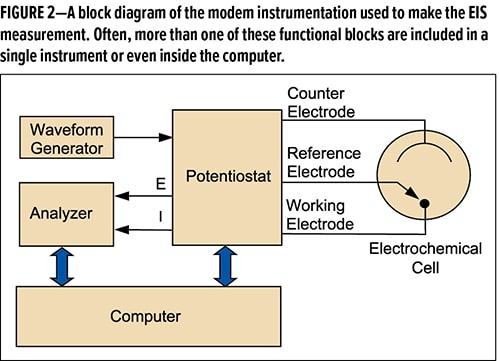

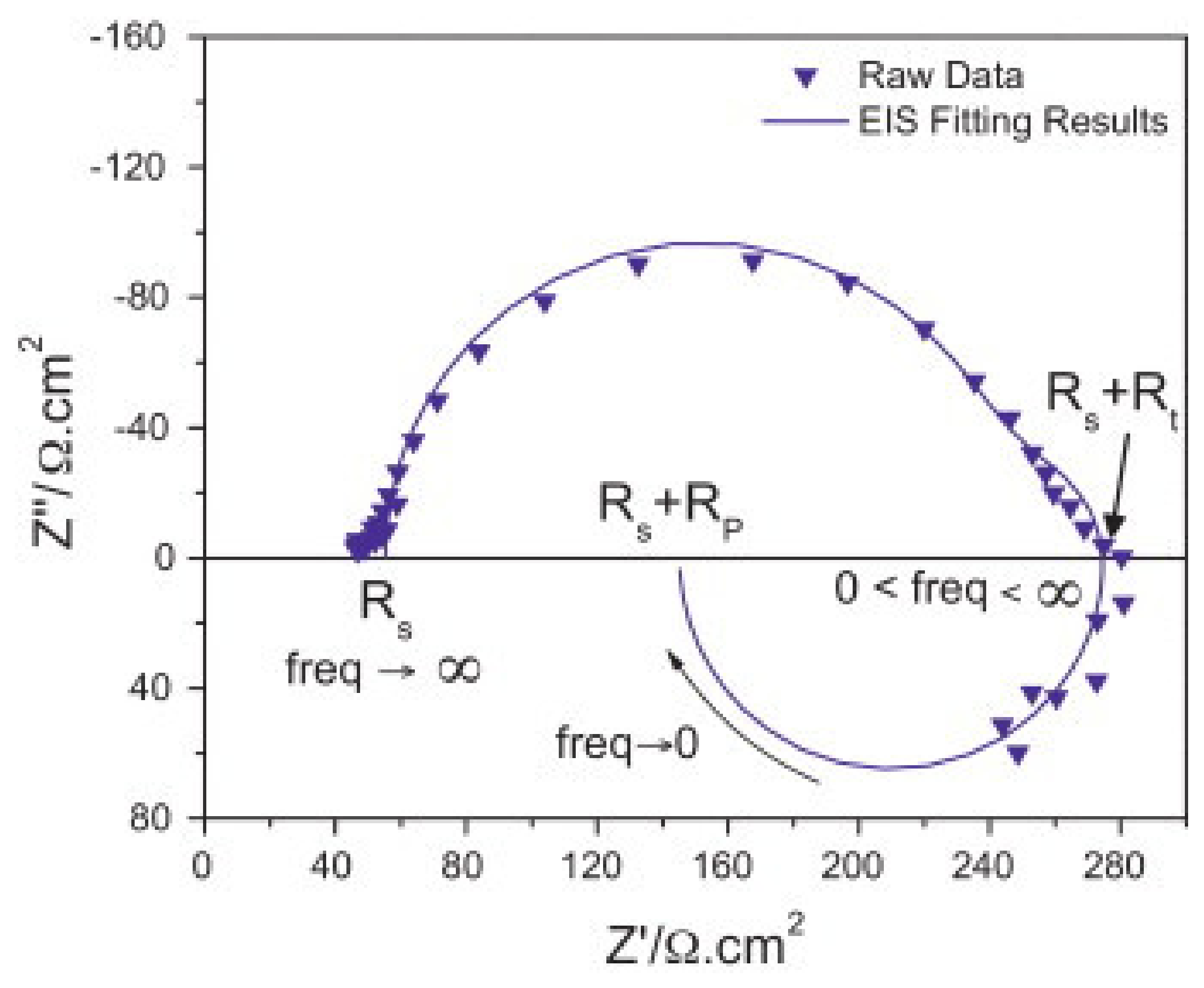

According to what was discussed in the last article concerning DC theory applying a DC voltage to a circuit one can measure the current whereby resistance is obtained by Ohms Law. Electrochemical impedance spectroscopy EIS has been used in various applications such as metal corrosion monitoring. Our capability covers both DC polarization techniques and AC impedance measurements and EIS.

Electrochemical impedance spectroscopy EIS is a non-destructive experimental technique used to characterise electrochemical processes such as corrosion. EIS Methods EIS experiments were carried out using 5 mV excitation from 105 to 102 Hz with 5 points per decade. The results acquired from the electrochemical impedance spectroscopy EIS study showed that DPH at a concentration of 1000 ppm has.

In addition to Corrosion Literature Search Supply CLSS our NACE certified corrosion specialist can also provide corrosion testing and monitoring services in accordance with international standards such as ASTM ISO BSI DIN JIS NACE and SIS. Subsequently a fitting process based on the simple Randles circuit can be. Electrochemical impedance spectroscopy serves as the method to measure or evaluate them.

Corrosionpedia Explains Electrochemical Impedance Spectroscopy EIS The majority of physio-chemical structures like oscillators and electro-chemical cells as well as biological tissues have dissipation properties and energy storage. EIS has been used widely in the laboratory for determining coating performance and for obtaining quanti- tative kinetic and mechanistic infor- mation on coating deterioration1-14The impedance of a coating is observed to decrease as a function of time of exposure to a corro-. Electrochemical impedance spectroscopy is a practical means frequently utilized for assessing the corrosion behavior of materials.

Laser Cladding Venture explains their approach. The atmospheric corrosion of coated samples can be examined by salt spray or fog testing.

Eis Test Results Of As Received Mechanically Polished And Download Scientific Diagram

Schematic Diagram Of The Electrochemical Impedance Spectroscopy Eis Download Scientific Diagram

Eis Yields Faster More Accurate Results In Corrosion Testing And Beyond Lubrizol

Corrosion Short Courses Electrochemical Impedance Spectroscopy Measurement Modeling Data Interpretation And Applications Presented By Nace Certified Corrosion Specialist Webcorr Corrosion Consulting Services

Exploring Electrochemical Impedance Spectroscopy American Coatings Association

Corrosion Consulting Services Corrosion Testing And Corrosion Monitoring

Corrosion Monitoring Using Ft Eis

Electrochemical Impedance Spectroscopy Eis A Review Study Of Basic Aspects Of The Corrosion Mechanism Applied To Steels Intechopen

Eis Plots Of Scratched Epoxy Coated Carbon And 3 Cr Steel After Download Scientific Diagram

Eis Yields Faster More Accurate Results In Corrosion Testing And Beyond Lubrizol

Evolution Of Eis For The Sample With Immersed Time In The Corrosion Download Scientific Diagram

Corrosion Testing Via Electrochemical Impedance Spectroscopy Eis Van Loon Chemical Innovations

Eis Of As Plated And Heat Trwweated Ni P Coatings After 10 H Of Download Scientific Diagram

Corrosion Testing Via Electrochemical Impedance Spectroscopy Eis Van Loon Chemical Innovations

Corrosion Tests A B Results Of Electrochemical Corrosion Tests Download Scientific Diagram

Electrochemical Impedance Spectroscopy Eis Bode Plots A And Nyquist Download Scientific Diagram

Schematic Diagram Of The Experimental Setup For Eis Download Scientific Diagram

Aluminium Foil Corrosion Italcoat Srl

Metals Free Full Text Electrochemical Impedance Spectroscopy For The Measurement Of The Corrosion Rate Of Magnesium Alloys Brief Review And Challenges Html

0 Response to "eis corrosion testing"

Post a Comment